We supply Replacement Parts for Microelectronics and Semiconductor Ultrapure Water Filtration Systems

We carry quartz sleeves and all parts for ETS, Aquafine, Ultra Dynamics, Trojan UV, Atlantic UV and Wedeco systems.

We carry Dow/Filmtec, Hydranautics, Osmonics, Desal, Koch, Toray and TriSep replacement RO membranes.

We carry filters for microfiltration, ultrafiltration and nanofiltration specifications from several suppliers.

In-stock items usually ship the same day. If we don't have some obscure part in stock, we'll try to track one down for you.

Whether you need valves, pumps, motors, gauges or any manner of replacement parts, you want us to be your first call.

Wendy Quinn started her water filtration parts business in 1986 with an initial focus on the semiconductor industry.

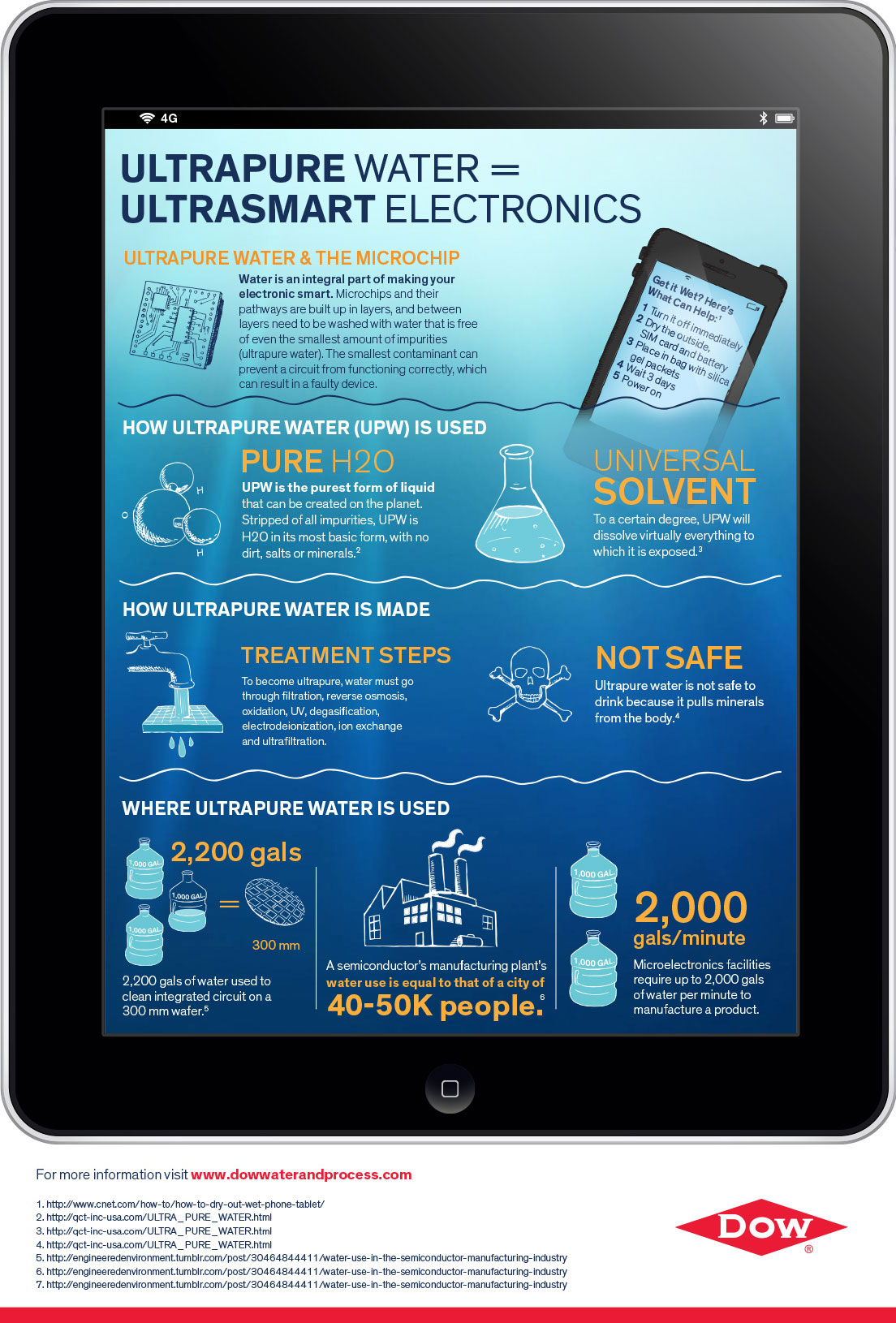

Ultrapure water is a commonly used term in the semiconductor industry to emphasize the fact that the water is treated to the highest levels of purity for all contaminant types, including: organic and inorganic compounds; dissolved and particulate matter; volatile and non-volatile, reactive and inert; hydrophilic and hydrophobic; and dissolved gases.

As the primary cleaning solvent used to rinse all contaminants and remnants of silicon etched away during the production process, Ultrapure Water (UPW) is essential in the fabrication of integrated circuits in the semiconductor and microelectronics industries.

Maintaining a reliable source of UltraPure Water (UPW) is vital to the microelectronics industry. Both semiconductor and microelectronics fabrication facilities require high-grade, ultrapure water as a key raw material throughout their manufacturing processes, whether for wafers, semiconductors, flat panels, photovoltaics or mass storage devices.

As semiconductor and integrated circuit manufacturers require large volumes of ultrapure water to rinse impurities from wafer surfaces, especially during sensitive photolithographic processes on the nanometer scale, a considerable business and environmental expense is incurred when the proper water filtration equipment is not employed or properly maintained.

The integrated circuits being produced today are so electron-microscopically minute and incomprehensibly complex that even the smallest contaminant can prevent a circuit from functioning properly. This could be a single spec of dust in the air or an invisible but troublesome element contained within a pool's worth of water.

Realizing that any contaminants decrease the production yield of usable circuits, the semiconductor industry requires much higher levels of water purity in order to maximize profits and reduce wastage on their production lines.

The amount of dissolved ionic solids, organics, live bacillus, suspended particulates and silica must therefore approach zero.

Since a single water treatment process cannot efficiently deliver water at the level of purity required by the semiconductor industry, experience have shown that water treatment solutions which take advantage of the specific capabilities of reverse osmosis (RO), ion exchange (IX) and other technologies are required.

Typically city feed water (containing all the unwanted contaminates previously mentioned) is taken through a series of purification steps that, depending on the quality of UPW wanted, includes gross filtration for large particulates, carbon filtration, water softening, reverse osmosis, exposure to ultraviolet (UV) light for total organic carbon (TOC) and/or bacterial static control, polishing using either ion exchange resins or electrodeionization (EDI) and finally filtration or ultrafiltration.

The ultrafiltration membranes and reverse osmosis elements supplied by Western Industrial as consumables and replacement parts are an ideal combination for producing high-quality, low-cost, reliable water needed to make today's extremely compact semiconductor chips.

Koch Membrane Systems is just one of our suppliers who offers customized high purity membrane systems for the semiconductor industry that swiftly remove contaminants such as colloidal silica, particles, total organic carbon, bacteria, and metal ions.

These membranes are also used for the treatment and recycling of wastewater from wafer washing and mechanical grinding operations.

Our reverse osmosis elements from Dow have been developed for the ultrapure market to meet the requirements of higher overall rejection, higher rejection of lower molecular weight organic compounds and silica, and an accelerated TOC rinse down profile.

DOW UltraFiltration is a water treatment technology with high chemical tolerance and fouling resistance, mechanically strong fibers, and adaptability to a wide range of feed water -- yielding consistent water quality, longer module life, and lower operating and maintenance costs. With its uniform pore size sub-structure that is reinforced with an ultra-fine pore selective layer, DOW™ UF is much more robust and resistant to constant air-scouring and fiber fatigue than most outside-in fibers.

Organic carbon, which is measured as total organic carbon (TOC), is one of the many impurities present in water. This impurity is found in water as either particulate organic matter, such as debris of vegetable and animal origin, microorganisms, and oily material, or in the form of soluble organic matter, such as fatty acids, organic acids, and nitrogenous matter (proteins, peptides and amino acids, sugars, dissolved organic gases such as methane, and synthetic organic compounds).

In the manufacture of high density semiconductor devices the defect density (ie. number of bad chips) correlates with the level of TOC in a pure water system so it is imperative to reduce or totally eliminate the TOC impurity in the feed source water system.

As such, the reduction of Total Oxidizable Carbon (TOC) is a primary objective of the microelectronics industry. TOC reduction can be assisted by using a special 185 nm synthetic UV lamp and quartz sleeve to break down low molecular weight organics through the dissociation of molecular bonds and the generation of aggressive hydroxyl radicals from water molecules that break-down organic compounds.

In the fabrication of an integrated circuit, Deionized (DI) water is used throughout the fabrication process. In fact, an integrated circuit may be exposed to DI water hundreds of times during its manufacture.

Because contaminants in deionized water can distort normal dopant profiles, create inversion layers or cause shorts, or circuit malfunctions, it is extremely important that semiconductor pure water be maintained at its highest attainable quality. The Semiconductor Equipment and Materials International (SEMI) recommendations for maximum acceptable levels of contaminants in Pure Water for Semiconductor Processing are shown in the SEMI F63 Suggested Guidelines. The requirements for UPW quality from the American Society for Testing and Materials International are included in the ASTM D5127 "Standard Guide for Ultra-Pure Water Used in the Electronics and Semiconductor Industries"

A variety of technical papers published in Solid State Technology, Ultrapure Water, and other technical journals document case studies of how ion chromatography has been used to maintain the best attainable quality water in Semiconductor Fabrication facilities. Ion chromatography is the only technique recommended by SEMI for inorganic anions. On-line ion chromatography provides the capability to continuously monitor ions at low part per trillion levels.

Ultraviolet (UV) treatment basically works in the same way strong sunlight purifies water by rendering any biological impurities inactive with certain lightwaves.

By destroying the very DNA of harmful pathogenic organisms, UV reduces the risk of contamination by preventing bacteria and viruses from being able to reproduce or perform vital cellular functions.

We supply replacement UV tubes, quartz sleeves and a variety of other parts from Neptune Benson/ETS, Aquafine, Ultra Dynamics, Trojan UV, Atlantic UV and Xylem/Wedeco.

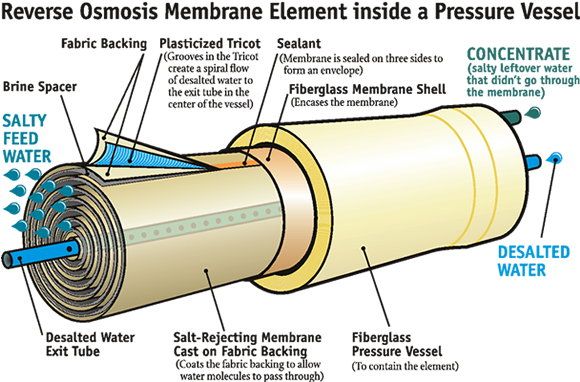

Reverse Osmosis Systems use a process that reverses the flow of water in a natural process of osmosis so that water passes from a more concentrated solution to a more dilute solution through a semi-permeable membrane with a pore size of approximately 0.0001 micron. Pre- and post-filters are often incorporated along with the reverse osmosis membrane itself, especially for microelectronics, printed circuit boards and semiconductor production.

Western Industrial can supply your ultrapure water treatment needs with parts and membranes for the Filmtec, Hydranautics, GE Osmonics, Toray, Desal, Koch and TriSep line of products. Here's more info on the Science and Application of Reverse Osmosis for Wastewater Treatment.

We can supply various water filter media such as diatomaceous earth, garnet, granular activated carbon, gravel, hematite, ilmenite, magnetite, manganese dioxide and sand.

To protect the filter’s membrane surface, pretreatment before filtration may include the addition of coagulants and powdered activated carbon, adjustments in pH or chlorine concentration levels.

We can supply you with instrumentation, Pentair control valves, ball-valves, butterfly-valves, needle-valves, floating-valves, gate-valves, forged-valves, check-valves, Y-strainers, joints and piping in brass, stainless steel or cast iron, plus pumps and motors from Grundfos, Goulds, Baldor, Wilden, LMI, Robusta, Kontro, Fristam, Fybroc, Jabsco, Paco, Pulsafeeder, Tonkaflo, Neptune, Walchem, Dayton, Hartell, Prominent, Ansimag, SIHI, Warrender, ARO, Little Giant and Torpedo.

Filtration is a physical process that occurs when liquids, gases or dissolved/suspended matter adhere to the surface or the pores of an absorbent medium which allows certain molecules to pass (ie. H2O).

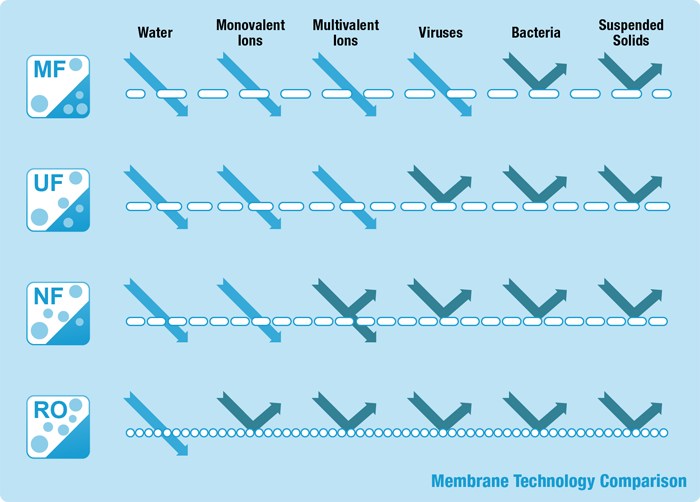

The choice of decontamination method required for each commercial / industrial water use application depends on the amount, size and charge of the contaminant particle needed to be blocked.

Using membrane filtration technology, reverse osmosis offers the finest degree of separation, followed by nanofiltration, ultrafiltration, and then microfiltration, which has the largest pore size, letting more contaminants pass through along with the water molecules.

A microfiltration filter operates at relatively low pressures and has a pore size of approximately 0.1 micron (pore size ranges vary by filter from 0.05 micron to 5 micron) and have a very high effectiveness in removing protozoa (ie. Cryptosporidium, Giardia); a moderate effectiveness in removing bacteria (e. Campylobacter, Salmonella, Shigella, E. coli); but is not effective in removing viruses (ie. Enteric, Hepatitis A, Norovirus, Rotavirus) or removing chemicals.

Ultrafiltration is the physical clarifying and decontaminating of water (removal of bacteria, viruses, algae, pollen, etc.) by passing it through porous, hollow-fiber PVDF membranes that hold back all unwanted particles.

Imagine, if you will, a large cartridge filled with bundles of long rubbery straws (membrane tubes) with dirty water on the inside or outside (process varies) of each straw, and clean water on the other.

Cleaner water passes through the membranes while certain contaminants are held back (based on pore size), then routinely back-washed by reversing the process (along with bursts of air to loosen the debris) and then discharged.

Ultrafiltration filters operate at relatively low pressures and have a pore size of approximately 0.01 micron (pore size ranges vary by filter from 0.001 micron to 0.05 micron; Molecular Weight Cut Off (MWCO) of 13,000 to 200,000 Daltons).

Ultrafiltration filters remove particles based on size, weight, and charge. They have a very high effectiveness in removing protozoa (ie. Giardia, Cryptosporidium) and bacteria (ie. Campylobacter, Salmonella, Shigella, E. coli); a moderate effectiveness in removing viruses (ie. Enteric, Hepatitis A, Norovirus, Rotavirus); and a low effectiveness in removing chemicals.

Nanofiltration filters have a pore size of approximately 0.001 micron (ranging by filter from 0.008 micron to 0.01 micron; Molecular Weight Cut Off (MWCO) of 200 to 2000 Daltons) and remove particles based on size, weight, and charge.

Nanofiltration has a very high effectiveness in removing protozoa (ie. Cryptosporidium, Giardia); bacteria (ie. Campylobacter, Salmonella, Shigella, E. coli); viruses (ie. Enteric, Hepatitis A, Norovirus, Rotavirus); and a moderate effectiveness in removing chemicals.

Please contact us whenever you need replacement parts for any type of water purification system component, regardless of manufacturer. Simply give us the part number and we'll provide you with a quote for your consideration and arrange delivery upon acceptance.

Kindly note that we do not design, manufacture, engineer, or service water treatment systems. Our business is focused solely upon offering you very low prices on consumables and repair parts for existing commercial and industrial OEM water purification systems, regardless of the application.

Our California office is open Monday through Friday from 8:00am to 5:00pm Pacific Standard Time, but you can write to us anytime and we'll get back to you as soon as possible, often after-hours, because we know that emergencies happen. We will ship worldwide with the exception of high fraud risk countries.

One of our goals is to continue to offer our customers the most up-to-date water treatment equipment and technology. So, if you are a water treatment component manufacturer looking for an established filtration parts and consumables wholesale distributor for your product line, or a procurement company seeking "women owned small business" bids for the government or an equal opportunity based publicly-traded corporate client, give us a call. We'd love to hear from you.