Western Industrial Inc. has supplied Replacement Parts for the Ultrapure Water Filtration Systems Industry for 30 years

We carry quartz sleeves and all parts for ETS, Aquafine, Ultra Dynamics, Trojan UV, Atlantic UV and Wedeco systems.

We carry Dow/Filmtec, Hydranautics, Osmonics, Desal, Koch, Toray and TriSep replacement RO membranes.

We carry filters for microfiltration, ultrafiltration and nanofiltration specifications from several suppliers.

In-stock items usually ship the same day. If we don't have some obscure part in stock, we'll try to track one down for you.

Whether you need valves, pumps, motors, gauges or any manner of replacement parts, you want us to be your first call.

Wendy Quinn started her water filtration parts business in 1986 with an initial focus on the semiconductor industry.

Ultraviolet (UV) treatment basically works in the same way strong sunlight purifies water by rendering any biological impurities inactive with certain lightwaves.

By destroying the very DNA of harmful pathogenic organisms, UV reduces the risk of contamination by preventing bacteria and viruses from being able to reproduce or perform vital cellular functions.

We supply replacement UV tubes, quartz sleeves and a variety of other parts from Neptune Benson/ETS, Aquafine, Ultra Dynamics, Trojan UV, Atlantic UV and Xylem/Wedeco.

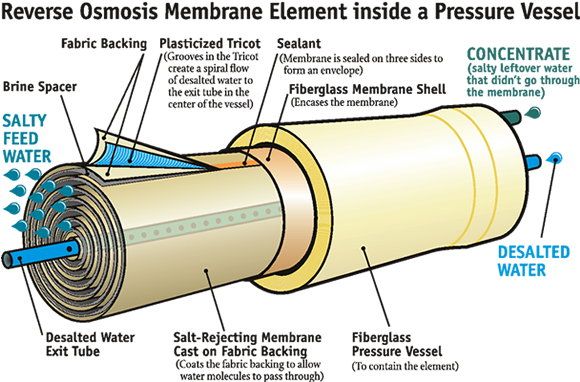

Reverse Osmosis Systems use a process that reverses the flow of water in a natural process of osmosis so that water passes from a more concentrated solution to a more dilute solution through a semi-permeable membrane with a pore size of approximately 0.0001 micron. Pre- and post-filters are often incorporated along with the reverse osmosis membrane itself, especially for microelectronics, printed circuit boards and semiconductor production.

Western Industrial can supply your ultrapure water treatment needs with parts and membranes for the Filmtec, Hydranautics, GE Osmonics, Toray, Desal, Koch and TriSep line of products. Here's more info on the Science and Application of Reverse Osmosis for Wastewater Treatment.

We can supply various water filter media such as diatomaceous earth, garnet, granular activated carbon, gravel, hematite, ilmenite, magnetite, manganese dioxide and sand.

To protect the filter’s membrane surface, pretreatment before filtration may include the addition of coagulants and powdered activated carbon, adjustments in pH or chlorine concentration levels.

We can supply you with instrumentation, Pentair control valves, ball-valves, butterfly-valves, needle-valves, floating-valves, gate-valves, forged-valves, check-valves, Y-strainers, joints and piping in brass, stainless steel or cast iron, plus pumps and motors from Grundfos, Goulds, Baldor, Wilden, LMI, Robusta, Kontro, Fristam, Fybroc, Jabsco, Paco, Pulsafeeder, Tonkaflo, Neptune, Walchem, Dayton, Hartell, Prominent, Ansimag, SIHI, Warrender, ARO, Little Giant and Torpedo.

Filtration is a physical process that occurs when liquids, gases or dissolved/suspended matter adhere to the surface or the pores of an absorbent medium which allows certain molecules to pass (ie. H2O).

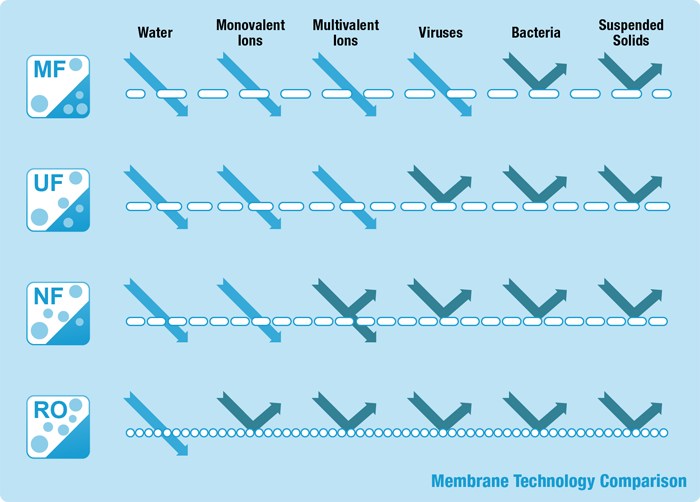

The choice of decontamination method required for each commercial / industrial water use application depends on the amount, size and charge of the contaminant particle needed to be blocked.

Using membrane filtration technology, reverse osmosis offers the finest degree of separation, followed by nanofiltration, ultrafiltration, and then microfiltration, which has the largest pore size, letting more contaminants pass through along with the water molecules.

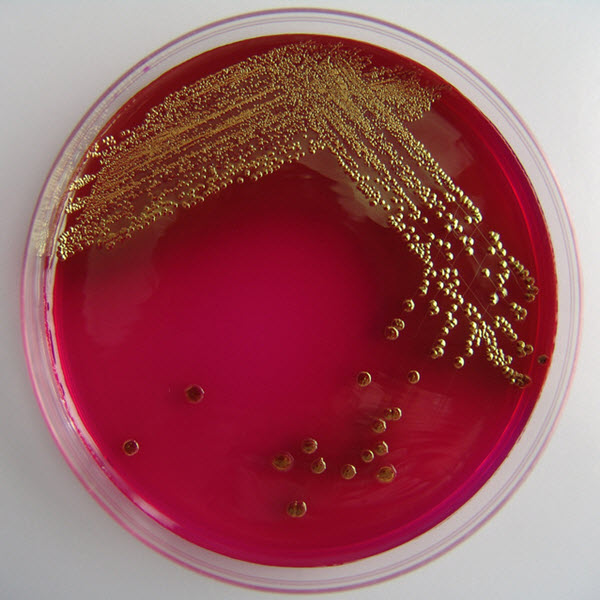

A microfiltration filter operates at relatively low pressures and has a pore size of approximately 0.1 micron (pore size ranges vary by filter from 0.05 micron to 5 micron) and have a very high effectiveness in removing protozoa (ie. Cryptosporidium, Giardia); a moderate effectiveness in removing bacteria (e. Campylobacter, Salmonella, Shigella, E. coli); but is not effective in removing viruses (ie. Enteric, Hepatitis A, Norovirus, Rotavirus) or removing chemicals.

Ultrafiltration is the physical clarifying and decontaminating of water (removal of bacteria, viruses, algae, pollen, etc.) by passing it through porous, hollow-fiber PVDF membranes that hold back all unwanted particles.

Imagine, if you will, a large cartridge filled with bundles of long rubbery straws (membrane tubes) with dirty water on the inside or outside (process varies) of each straw, and clean water on the other.

Cleaner water passes through the membranes while certain contaminants are held back (based on pore size), then routinely back-washed by reversing the process (along with bursts of air to loosen the debris) and then discharged.

Ultrafiltration filters operate at relatively low pressures and have a pore size of approximately 0.01 micron (pore size ranges vary by filter from 0.001 micron to 0.05 micron; Molecular Weight Cut Off (MWCO) of 13,000 to 200,000 Daltons).

Ultrafiltration filters remove particles based on size, weight, and charge. They have a very high effectiveness in removing protozoa (ie. Giardia, Cryptosporidium) and bacteria (ie. Campylobacter, Salmonella, Shigella, E. coli); a moderate effectiveness in removing viruses (ie. Enteric, Hepatitis A, Norovirus, Rotavirus); and a low effectiveness in removing chemicals.

Nanofiltration filters have a pore size of approximately 0.001 micron (ranging by filter from 0.008 micron to 0.01 micron; Molecular Weight Cut Off (MWCO) of 200 to 2000 Daltons) and remove particles based on size, weight, and charge.

Nanofiltration has a very high effectiveness in removing protozoa (ie. Cryptosporidium, Giardia); bacteria (ie. Campylobacter, Salmonella, Shigella, E. coli); viruses (ie. Enteric, Hepatitis A, Norovirus, Rotavirus); and a moderate effectiveness in removing chemicals.

Fecal Coliform and Dysentery Bacilli are bacteria that cause diarrhea. Salmonella bacteria causes food poisoning. Legionella Pneumophila bacteria causes Legionnaires' Disease, Streptococcus causes Strep Throat and Staphylococcus causes boils.

Influenza is a virus which causes the flu and Bacteriophage (E. Coli) is a virus which causes diarrhea. Other waterborne viruses include Enteric, Hepatitis A, Norovirus, Adenovirus and Rotavirus.

Industries that rely upon ultrapure water, such as micro-electronics and semiconductor clean rooms, simply can't afford to have impurities in their source water.

Water treatment can remove chemicals / minerals such as iron, sediment, sand, calcium, lime, rust, chlorine, arsenic, fluoride, metals, magnesium, manganese ions, residual salts and ionizable aqueous species (such as carbon dioxide, silica, ammonia and boron).

Subdivisions, mobile home parks, water districts, cities, towns and villages.

Schools, child care facilities, businesses.

Western Industrial supplies municipalities and water districts with all of their consumables and water purification system parts such as reverse osmosis membranes, UV lamps, filter cartridges, replacement media, valves and more.

Conventional drinking water treatment facilities typically incorporate: 1) coagulation and flocculation, in which dirt, colloids and other suspended particles in the water column bind to alum or other chemicals that are added to the water to form floc; 2) sedimentation, in which the coagulated particles (floc) settle to the bottom; 3) filtration, in which particles including clays, silt and organic matter are physically removed; and 4) disinfection, in which microorganisms are killed or inactivated.

In addition, water treatment facilities may utilize advanced treatment options such as nanofiltration and ultrafiltration, reverse osmosis, ion exchange and carbon adsorption (Note: different than absorption) to remove contaminants not removed by conventional filtration.

Whether you’re new to the water treatment industry or an experienced professional, the Dow Water Academy from their Water and Process Technology division offers direct access to leading experts in water treatment technology for reverse osmosis, nanofiltration, ion exchange, ultrafiltration, self-cleaning filters, and electro de-ionization.

Upon successful completion of courses, training certificates are provided to public and private sector water treatment operators, engineers, utility and plant managers.

Please contact us whenever you need replacement parts for any type of water purification system component, regardless of manufacturer. Simply give us the part number and we'll provide you with a quote for your consideration and arrange delivery upon acceptance.

Kindly note that we do not design, manufacture, engineer, or service water treatment systems. Our business is focused solely upon offering you very low prices on consumables and repair parts for existing commercial and industrial OEM water purification systems, regardless of the application.

Mind you, because we work extensively with the manufacturers, suppliers and installers of complete water filtration systems, we will do our best to refer any such inquiries to a trusted partner so that all your needs are met.

Our California office is open Monday through Friday from 8:00am to 5:00pm Pacific Standard Time, but you can write to us anytime and we'll get back to you as soon as possible, often after-hours, because we know that emergencies happen. We will ship worldwide with the exception of high fraud risk countries.

One of our goals is to continue to offer our customers the most up-to-date water treatment equipment and technology.

So, if you are a water treatment component manufacturer looking for an established filtration parts and consumables wholesale distributor for your product line, or a procurement company seeking "women owned small business" bids for a State or Federal government contract, or an equal opportunity based publicly-traded corporate client needing a WOSB set-aside government contract partner, give us a call. We'd love to hear from you.

DUNS # 175482512 / CAGE# 1GYJ8 / SBA Certification

North American Industry Classification System (NAICS) (restrictions in brackets below)

221310 - Water supply and irrigation systems (primarily filtration consumables and parts)

221320 - Sewage treatment facilities (primarily purification consumables and parts)

423830 - Water treatment equipment, industrial merchant wholesalers (primarily spare parts and consumables)

423850 - Water treatment equipment, municipal merchant wholesalers (primarily replacement parts and consumables)

423720 - Water softening and conditioning equipment merchant wholesalers (repair parts for water systems)

Federal Procurement Data System Product Service Codes

4610 - Water Purification Equipment (repair parts, replacements, consumables)

6640 – Laboratory Equipment & Supplies (water-related device parts and consumable filters and membranes only)

National Institute of Governmental Purchasing NIGP class codes

890-02 Activated Carbon Systems, Equipment, and Absorbers

890-03 Back Flow Preventers for Water/Sewer Pipe

890-16 Complete Water Treatment Systems, Nonchemical: Ultraviolet Water Supply Sterilization, etc.

890-20 Demineralizers: Reverse Osmosis, etc.

890-22 Desalination Equipment, Water Treatment

890-23 Elements, Primary (Flow, Pressure, Temperature, etc.)

890-24 Filtration Equipment and Accessories, Water

890-28 Instrumentation Equipment, Parts and Accessories (Actuators, Analyzers, Regulators, Controllers, Transducers, etc.)

890-44 Meters, Water

890-45 Meter Fittings, Water, Accessories, Parts, and Conversion Kits

890-46 Meter Reading Devices

890-49 Ozone and Oxygen Generating Equipment and Parts

890-52 Removal Equipment, Water Treatment: Ammonia, Bacterial, Iron, Etc.

890-65 Sewage and Waste Treating Equipment and Supplies

890-69 Sumps, Parts, and Accessories

890-70 Switches (Pressure, Flow, Level, Proximity, Temperature, etc.)

890-74 Transmitters (Pressure, Flow, Level, etc.)

890-76 Virus and Bacteria Inactivation, Ozone Type Equipment

890-77 Waste Water Reclamation Systems And Parts

890-78 Water Filters and Filter Elements (Except Boiler, Photo Darkroom, and Swimming Pool): Cartridges, etc.

890-79 Water and Wastewater Disinfecting Ozonators

890-85 Water Softening Equipment, Ion Exchange Type

890-86 Water Systems, Ultra Pure

890-87 Water Treatment Equipment (Not Otherwise Classified)

885-08 Activated Carbon and Filter Elements

885-80 Resins, Sodium Ion Exchange (For Water Softening)

720-06 Barrel Pumps (Drum Pumps), Rotary and Plunger Types, Hand Operated

720-12 Booster or Circulating Pumps, In-Line

720-15 Centrifugal Pumps, Portable

720-17 Centrifugal Pumps, Compact, Submersible

720-18 Centrifugal Pumps, Stationary

720-24 Diaphragm Pumps

720-36 Hydraulic Pumps, Hand and Motor Driven

720-40 Mechanical Pumps and Accessories

720-52 Propeller Pumps, Vertical

720-55 Proportioning Pumps: Chemical Feed, Metering, Positive Displacement, and Injector Pumps

720-56 Pumps, Miscellaneous (Not Otherwise Classified)

720-73 Sump Pumps, Submersible and Non-Submersible

720-82 Water Pumps and Accessories

690-62 Recorders, Circular and Strip, and Accessories (Including Chart Paper, Pens)

690-64 Regulators, Flow, Pressure

690-68 Relays, etc.

690-79 Switches, Temperature Pressure

690-84 Test Equipment, Analog and Digital

690-87 Transducers, Signal Converter

690-88 Transmitters, Pressure

670-69 Valves, Brass and Copper

670-70 Valves, Bronze: Angle, Ball, Check, Gate, Globe, etc.

670-71 Valves, Butterfly, All Kinds

670-75 Valves, Iron Body: Angle, Check, Gate, Globe, etc.

670-77 Valves, Plastic: Ball, Check, Diaphragm, Globe, etc.

670-80 Valves, Solenoid Control

670-81 Valves, Stainless Steel: Angle, Ball, Check, Gate, Globe, etc.

670-82 Valves, Steel: Angle, Check, Gate, Globe, etc.

670-93 Water Softening Equipment, Commercial

Federal Supply Group Classification codes:

46 – Water purification & sewage treatment equipment

Looking for used water filtration equipment? We might have a client who is looking to sell their second-hand purification units after they've been replaced by a larger capacity system.